Level Module Setup

Fundamentals

The Fuellox Level Gauge (LG) is a wet part, that is its submerged in the fuel. It is actually a pressure sensor and measures liquid height from the pressure of the diesel.

Each time someone dispenses fuel from the tank the level is measured and updated on the system.

In most cases the Fuellox Installer, or Tank Supplier will complete these steps. This guide is to assist those less familiar with the setup process.

Level Gauge Setup Process

Time estimates are suggested for first time LG Installers.

- Probe Installation - 60 mins

- Wiring - 30 mins

- Prepare Strapping Table - 10mins

- Hardware Configuration - 5 mins

- Level Calibration - 15 mins

- Notifications & Alerts

- Reporting

- Maintenance

- Other Considerations

1. Probe Installation

Locate a spare port on the top of the tank. Look for a 2” threaded port which are best, although a 1” can work as well.

You’ll need to cut a hole into that fitting that can take a cable gland. Fit the gland and run the cable through so the sensor can be submerged into the fuel.

Be sure to the use a suitable sealing compound on the tank fitting to prevent water ingress. Leave the cable gland loose, so the fitting can be threaded in without twisting the LG cable.

Once the fitting is replaced back into the tank, adjust the sensor so its in the bottom of the tank. You should be able to hear and feel the sensor contacting the bottom of the tank.

Its adviseable to check the tank for water before installing the probe. If there is water in the bottom in the tank, then remove that and any dirt or debris before installing the LG. Water and Dirt can foul and damage the LG.

Make the final adjustments to the line and cable gland to ensure the probe is at the bottom of the tank. If there is excess line it can be left in the tank. If there is not enough cable use a suitable insulated cable to extend the LG cables to the Fuellox unit.

Do not interfere with the black breather line. That can be terminated in a junction box, however a weather proof breather will be needed. That line needs to vent to free air so the tube pressure can equalize. This is critical to the performance and reliability of the LG.

2. Wiring

Connect the red wire to J17-VBAT and the green sensor wire to J17-4-20mA

| Probe Wire | Description | Fuellox Board | Fuellox DIN |

|---|---|---|---|

| Red | Power | J17-VBAT | 18 - Red Screw in |

| Green | Sensor | J17-4-20mA | 19 - Green Screw In |

| Black | Breather | Open | none |

| Other | Not Applicable | N/A | none |

Some Fuellox units (ie 204V AC systems) come with a DIN rail. In these cases the PCB Wiring is brought out to the DIN Rail See Here.

3. Create the Strapping Table

Make a note of the Safe Fill Level (SFL) on the dip stick.

Create a list of measurements from the dip stick. Record the mm height and the dip stick volume in Litres.

Example Strapping Table

| Liquid Diesel (mm) | Volume Litres (L) |

|---|---|

| 0 | 200 |

| 290 | 5,860 |

| 590 | 7,710 |

| 880 | 9,570 |

| 1180 | 11,430 |

| 1470 | 13,290 |

| 1760 | 15,140 |

| 2060 | 17,000 |

| 2350 | 18,860 |

| 2650 | 20,000 |

Submit your strapping table worksheet to the Help Desk in advance of the level commissioning and tank setup.

Data points

| Tank Style | Recommendation |

|---|---|

| Cubes, to 1.3m high | 4-5 points is plenty |

| Containerised to 2.7m high | 6-8 points |

| Bullet tanks & Horizontal Cylinders | 15-20 points |

| Vertical tanks > 3m | Alternative probe required |

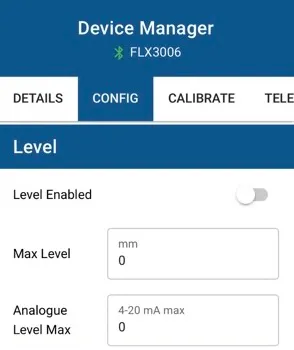

4. Configuration

Hardware settings are updated via the mobile app. Note this is a once time configuration completed at the point of commissioning the LG.

From the Fuellox App, enter the Device Manager. If you don’t have access, call the help desk and request addition of the Fuellox permission “Customer Manage Devices”.

Enable the level module as follows:

Hardware Settings

| Setting | Value |

|---|---|

| Level Enabled | On |

| *Max Level | 2700 |

| *Analogue Level Max | 20 |

Apply the settings as shown

- Click Save

- Await the 2x Green notifications

- Power Cycle the unit

You will need to create at least one Fuellox transaction before moving to the next step.

5. Level Calibration

Once the LG is installed, and the strapping chart is uploaded its time to calibrate the LG. There are some advantages to completing the calibration when the tank is full.

To calibrate the unit, get the help desk on a call. Manually take a tank dip, and report that volume, and mm height back to us. We’ll use that calibration with the latest data point to make adjustments as needed.

Data needed for calibration

| Data | Reported Value Units |

|---|---|

| Actual Dip Volume | Litres |

| Liquid Height | mm Height |

When the calibration is updated you will need to

- Sync the Fuellox app, to get the updated calibration data

- Complete a test dispense.

- Confirm the reported tank level and the actual tank level

Sometimes the calibration needs to be adjusted after the first attempt.

Over the next few days/weeks periodically confirm the LG measurement to the actual tank level via the dip stick.

If there are major variances, another calibration should be completed.

6. Notifications & Alerts

Installers and Resellers can create notifications for LG customers. Access to the Fleet level Fuellox service is required for LG support.

The Help Desk can also setup notifications for you too.

LG notifications can be configured a few ways.

Scheduled: each day, at a set time the levels will be checked and notifications sent.

Immediate: as soon as the tank level falls below the set point the notification will trigger.

Immediate events are triggered just once. Should you miss the email or SMS, you won’t receive another notification. Scheduled events will run every day. So if you miss an email one day, they come every day until the fuel level goes above the set point.

There are 2 types of notification set points.

Warning: Is to give advance notice of a low point, get updated pricing from your suppliers.

Reorder: Indicates its now time to place the order with the supplier.

We suggest conservative set points until the LG is confirmed to be accurate.

Notifications can be delivered via email or sms.

Be sure to include several team members so that in the event of leave, illness or staff changes the notification is not missed.

LG notifications can also be addressed to your fuel supplier allowing them to schedule your delivery.

7. Reporting & Access

The LG data can be displayed on the web app and the mobile app.

Be sure to let the help desk know which team members require access and if that access is web, mobile or both.

8. Maintenance

- Keep the tank clean and free from water

- If there is a high risk of water ingress to the tank, locate the probe above the water layer. Be sure to recalibrate the level after moving the probe.

- Periodically inspect the probe, in line with normal tank maintenance and inspection routines

- Periodically compare the actual vs reported tank levels, at least weekly for the first month

- If the probe is damaged and data is not updating notifications may not be generated. Its the responsibility of the customer to ensure the equipment is operational at all times.

LG Performance

Where the LG fails to produce sufficiently accurate data consider the following:

- Update the strapping chart with more data points

- Confirm the fuel density with the fuel supplier and advise the help desk

- Confirm the black breather tube to the LG Sensor is not obstructed in any way

- Re Calibrate the LG when its full

- Be conservative with warning and reorder points

- Manually dip the tank from time to time and compare

9. Other Considerations

Expect some variation in level accuracy and precision from time to time. Diesel fuel is subject to thermal expansion and the LG precision can change over time and with temperature and seasonal fluctuations.

Where tanks do not sit on a flat level surface the geometry of your liquid body will not match the dip stick measurements. Additional margins for error must be allowed for in the rounding setting.

The Reported Level is only for delivery scheduling. The tank level is insufficient for auditing Fuellox over time. Where an audit capability is required a totalising meter should be installed.

The LG is designed for use in static tanks. Operation in mobile tanks and service trucks is prone to error and inconsistent results.

The LG is not compatible with any hazardous material such as ULP, or Aviation fuels. Strictly for use with lubricating oils, diesel and DEF.

Use of the LG is at the customers risk. Fuel stockout due to misuse, poor maintenance, installation or configuration is the sole responsibility of the user at all times.